CAST7

Our Products

Grate bars

- Material Durability

- Heat Resistance

- Quality Surface Finish

- Design and Dimensions mastering

- Recipe for chemical Compatibility

- Easy Maintenance and Replacement

Grate bars

- Material Durability

- Heat Resistance

- Quality Surface Finish

- Design and Dimensions mastering

- Recipe for chemical Compatibility

- Easy Maintenance and Replacement

Side walls (upper and lower) – Heat resistance and durability

- Thermal insulation

- Heat resistance

- Structural strength

- Corrosion resistance

- Easy maintenance

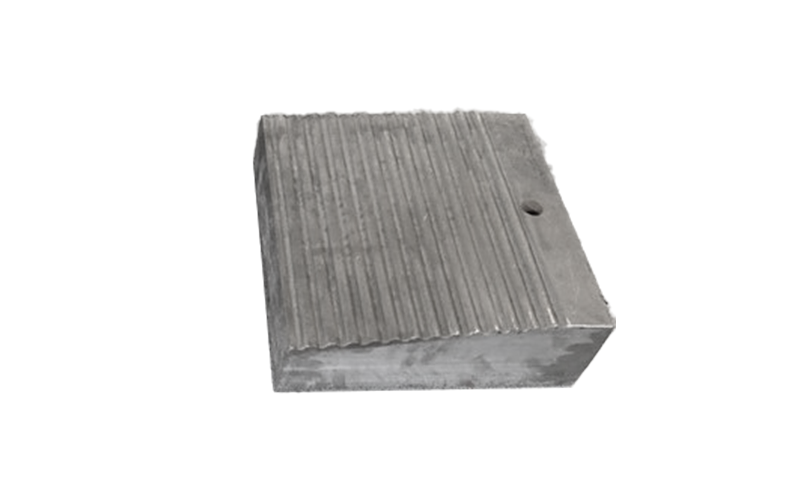

Grate plates

Grate plates are an integral part of grate-kiln induration furnace system. They play a vital role in achieving successful and efficient pellet induration. They serve as the base or platform on which the iron ore pellets travel during the pre-heating process. Grate plates are designed to provide support and distribute the weight of the pellet bed evenly across the blanket.

They facilitate the proper flow of air and heat through the pellet bed. The design and spacing of the openings are important for achieving uniform air distribution and optimal heat transfer throughout the pellet bed. Our grate plates provide a smooth surface on which the pellets can slide or roll during the pre-heating process, minimizing pellet damage or abrasion for consistent pellet quality.

- Durability

- Optimal perforation design

- Smooth surface

- Easy maintenance

- Proper dimensions

- Resistance to corrosion

- Compatibility with pellet characteristics

Grate plates

Grate plates are an integral part of grate-kiln induration furnace system. They play a vital role in achieving successful and efficient pellet induration. They serve as the base or platform on which the iron ore pellets travel during the pre-heating process. Grate plates are designed to provide support and distribute the weight of the pellet bed evenly across the blanket.

They facilitate the proper flow of air and heat through the pellet bed. The design and spacing of the openings are important for achieving uniform air distribution and optimal heat transfer throughout the pellet bed. Our grate plates provide a smooth surface on which the pellets can slide or roll during the pre-heating process, minimizing pellet damage or abrasion for consistent pellet quality.

- Durability

- Optimal perforation design

- Smooth surface

- Easy maintenance

- Proper dimensions

- Resistance to corrosion

- Compatibility with pellet characteristics

If a picture is worth 1,000 words, then a part is worth 1,000 pictures!

AT CAST7 we excel at ensuring an exceptional quoting process that guarantees customers receive precisely what they need in terms of specifications, while upholding high-quality standards and timely delivery.

Acquiring sample parts from the customer is an integral and necessary aspect of the quoting process that cannot be overlooked. If you are looking for a brand-new product and only have a print, we have the in-house engineering available to create 3D models and design the molding tools to achieve exactly what you’re looking for!